SAVEWO

THE BEST · MAKING THE BEST

SAVEWO, an innovative company specialised in the development, design and production of health protection gear, was founded in 2020 with an aim to contribute to the local and global fight against COVID-19 and create products that can make Hong Kong proud. The world-class capabilities of our mask products have been confirmed by various renowned professional testing and certification bodies, including Nelson labs / SGS / TUV / KOTITI / STC / Bureau Veritas. SAVEWO is the first mask manufacturer in Hong Kong to mass-produce protective respirators certified under KF94 / KF99 (Korea) and EN149: 2001+A1: 2009 FFP2 / FFP3 (EU) standards.

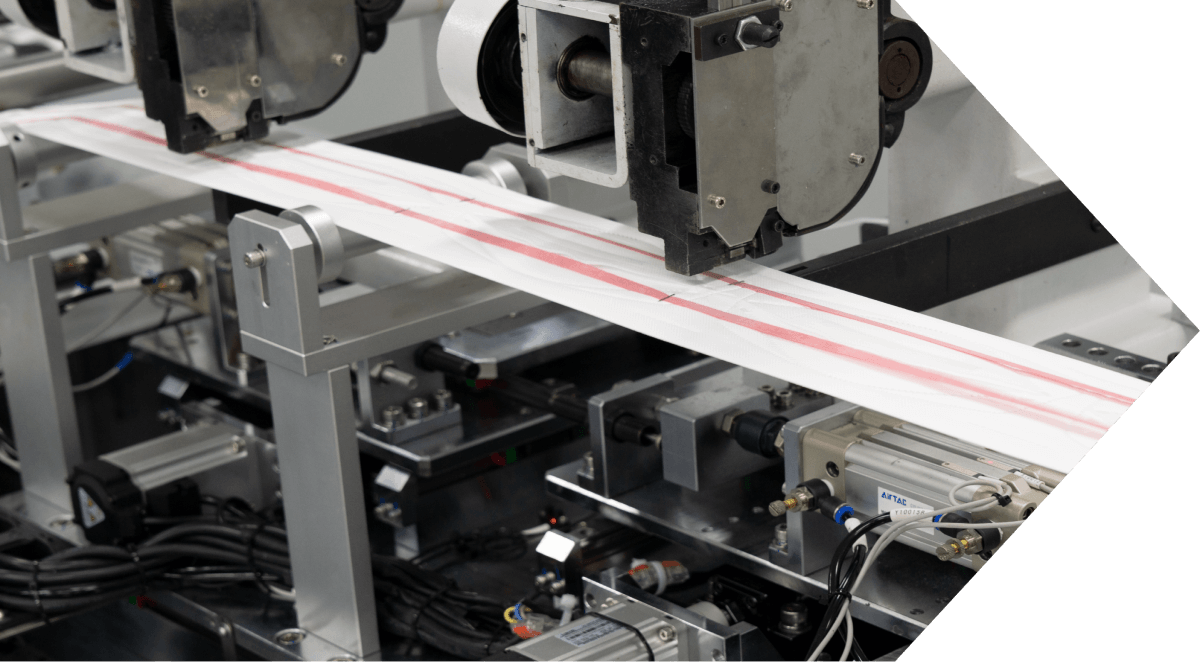

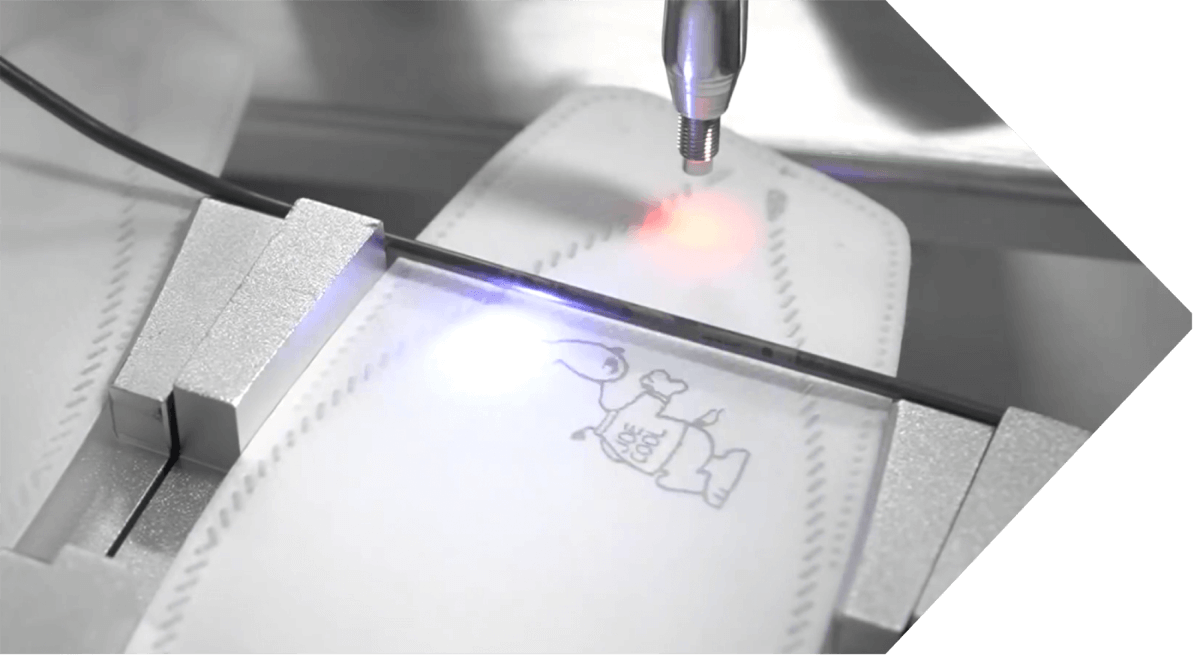

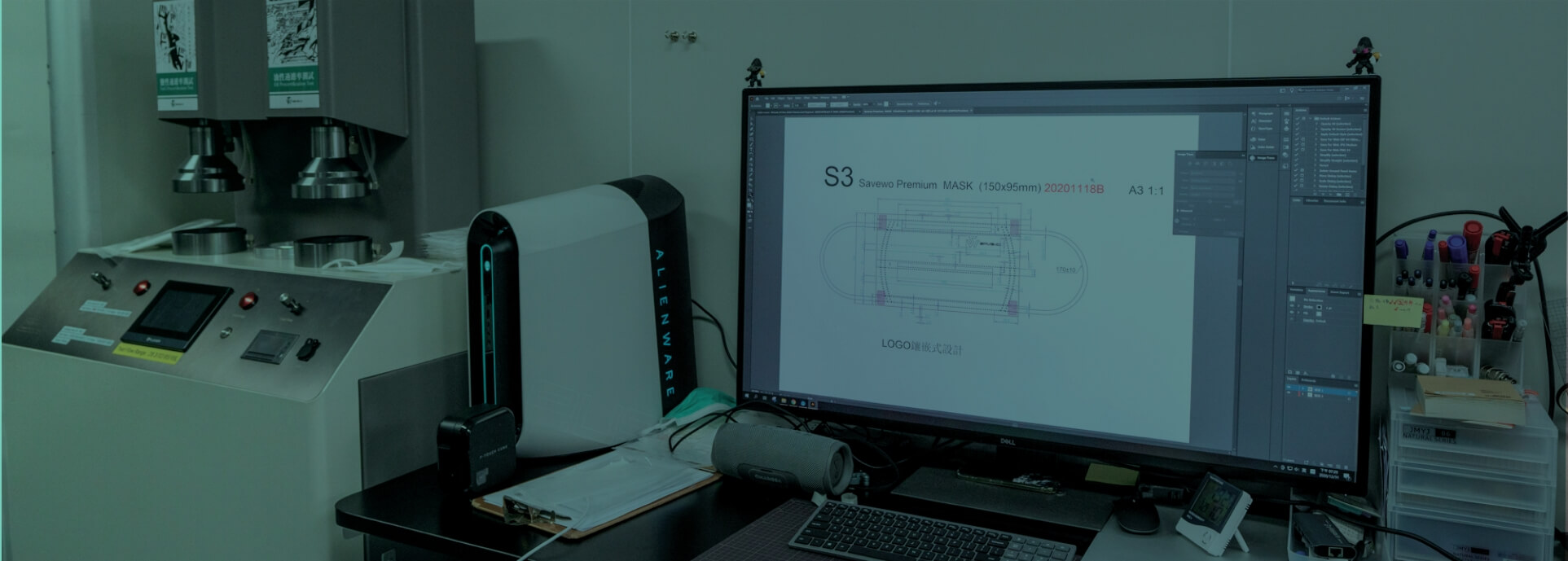

Flagship Production Facility

3DMASK Ultra

3DMASK Extreme Pro

3DMASK Smile

3DMEOW

3DBEAR

PremiumMask

Kamen Rider Mask

(Sodium Chloride Test) ≥ 99%

Oily Particle Filtration Efficiency

(Paraffin Oil Test) ≥ 99%

Bacterial/Particle/Viral Filtration Efficiency

(BFE/PFE/VFE) ≥ 99%

Guaranteed Filtration Efficiency > 24 Hours

Filtration efficiency maintained 99.9% upon exposure to 100% relative humidity for 24 hours

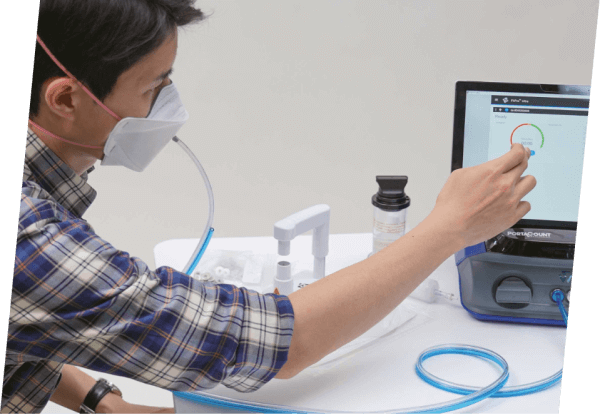

composite filtration technology provides for a highly breathable material with differential pressure resistance < 6mmH2O/cm2 . Breathing Resistance < 3.9mmH2O, less than half of the breathing resistance of traditional FFP3 respirators with no valve plugs.

composite filtration technology provides for a highly breathable material with differential pressure resistance < 6mmH2O/cm2 . Breathing Resistance < 3.9mmH2O, less than half of the breathing resistance of traditional FFP3 respirators with no valve plugs.

airtight seal and

airtight seal and elastic headband is compatible with more than 90% of adults, ensuring a safe, comfortable fit on the face.

elastic headband is compatible with more than 90% of adults, ensuring a safe, comfortable fit on the face.

material is designed to balance the pressure on the head and the neck to facilitate blood flow.

material is designed to balance the pressure on the head and the neck to facilitate blood flow. airtight seal is made of a special soft material to distribute the pressure of the respirator evenly on the user and relieve strain. The inner layer is composed of

airtight seal is made of a special soft material to distribute the pressure of the respirator evenly on the user and relieve strain. The inner layer is composed of skin-friendly material, which provides maximum comfort unlike traditional respirators.

skin-friendly material, which provides maximum comfort unlike traditional respirators.

airtight seal and

airtight seal and elastic headband is compatible with more than 90% of adults, ensuring a safe, comfortable fit on the face.

elastic headband is compatible with more than 90% of adults, ensuring a safe, comfortable fit on the face.

material is designed to balance the pressure on the head and the neck to facilitate blood flow.

material is designed to balance the pressure on the head and the neck to facilitate blood flow. airtight seal is made of a special soft material to distribute the pressure of the respirator evenly on the user and relieve strain. The inner layer is composed of

airtight seal is made of a special soft material to distribute the pressure of the respirator evenly on the user and relieve strain. The inner layer is composed of skin-friendly material, which provides maximum comfort unlike traditional respirators.

skin-friendly material, which provides maximum comfort unlike traditional respirators.

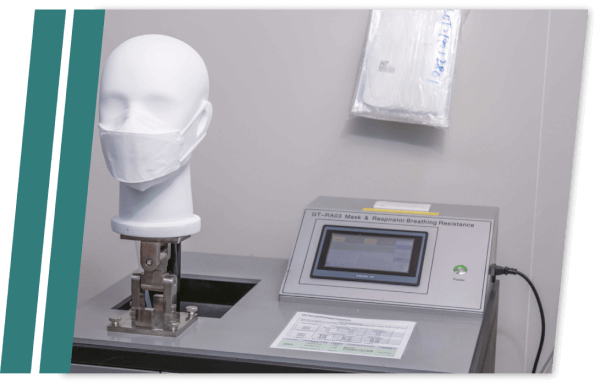

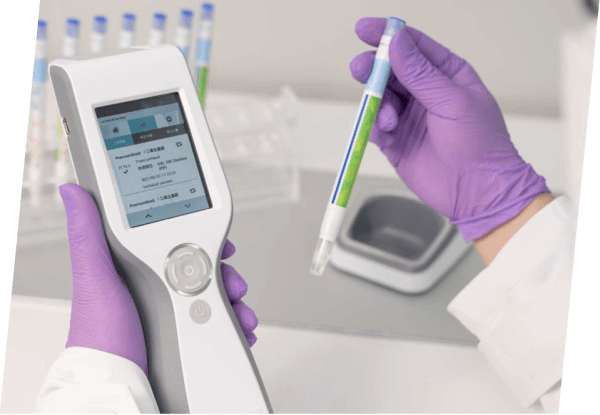

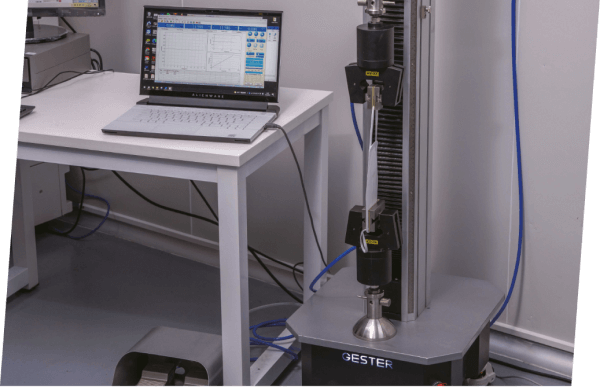

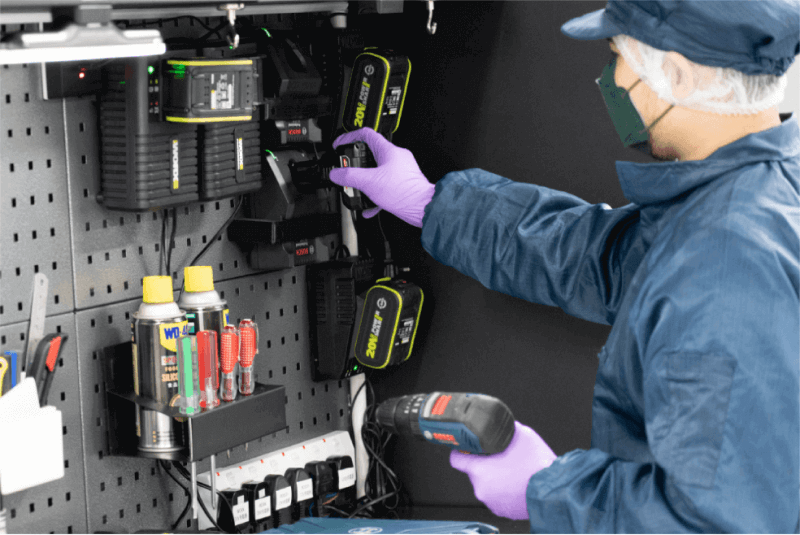

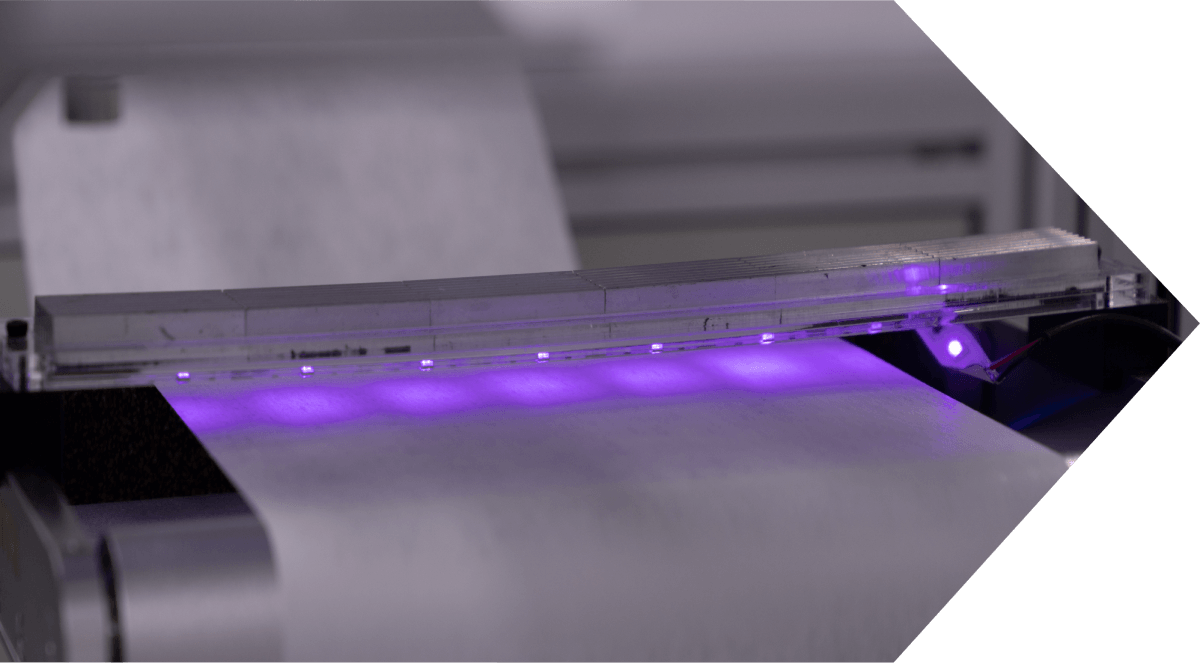

Professional Testing Equipment